INSTRUMENTATION

THE DIRECTOR CLASSIC

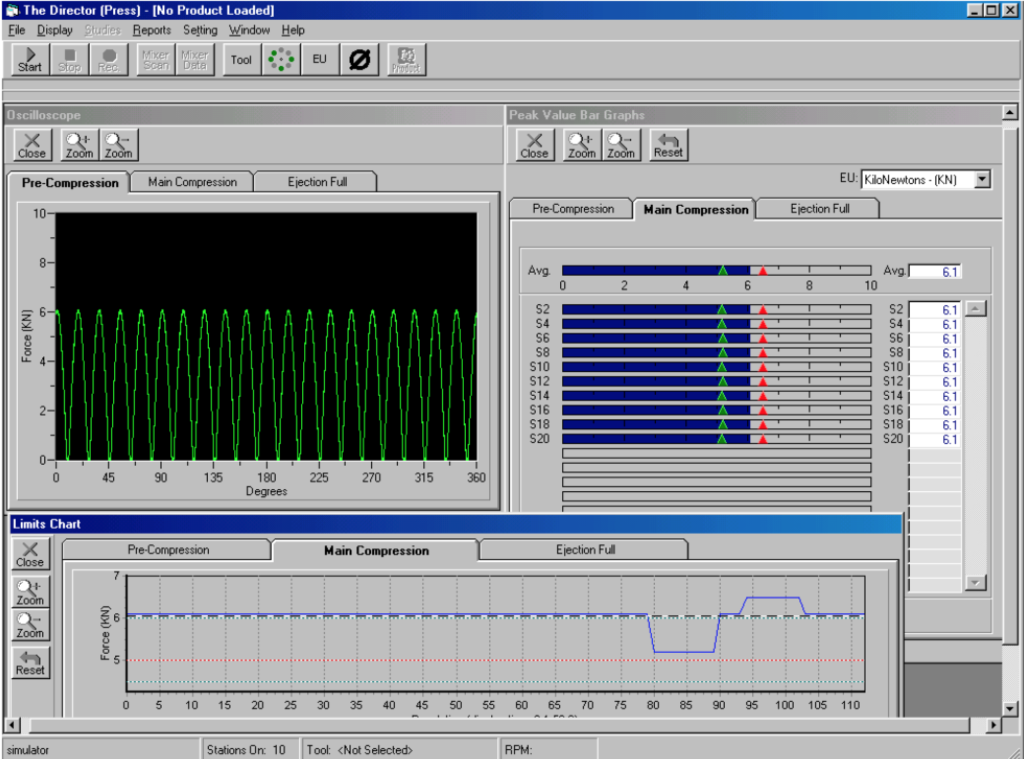

“The Director” Program is designed to acquire, display and analyze incoming data from transducers installed in tablet presses, mixers, granulators, roller compactors and other machines used within the pharmaceutical industry. It is capable of acquiring data at a rate of 10,000 samples per second per transducer, while offering real time displays in engineering units of force pressure in the US Standard, Metric or SI conversions. The program will guide an unfamiliar user through the necessary steps to achieve a desired goal and print summary reports of the results upon completion.

The tablet press module has built in sub-programs to acquire data in a manner appropiate for specific purposes such as performing a compaction profile, detailed analysis of a single compaction event or statistical analysis of a longer production run. For each sub-program there is a set of on screen instructions informing the user of how to perform the task at hand.

“The Director” will set up studies and experiments to guide you from research, to scale up, through production. Each display can be opened numerous times to achieve the desired look. Each display has tabs at the top allowing the user to select the transducer to be observed. The user can toggle between the transducers during the running of the tablet press if desired.

At the end of a study, the user may wish to generate reports. “The Director” is capable of generating fully formatted and human readable reports, based on the data collected.

THE SCALABILITY TOOL

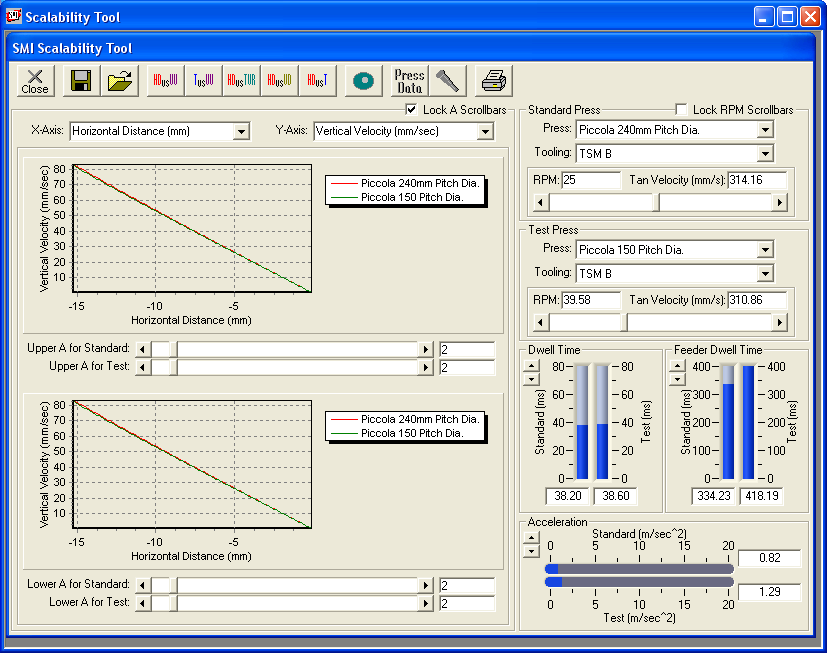

Small bench top tablet presses can be used to successfully transfer a product into larger production machines provided that the proper tooling and speeds are selected. “The Director Software V4 Scalability Program” can successfully predict the operating parameters for any machine to match the loading rates of another.

A mathematical relationship was developed taking into consideration factors such as turret pitch circle diameter, turret speed, compression roll diameters, feeder residence time and punch head geometry. These parameters were programmed into the “Director Software V4” that would calculate the rate of force application, duration the peak force, and time under the feeder for die fill for a specific tablet machine. The program permits visual displays for direct comparison between two selected machines. The user can vary the machine speeds (rpm) in an attempt to achieve similar loading profiles.

REQUEST INFORMATION FROM SMI

Have questions about our tablet presses or services? Contact us here and we will reach out to you.

HOURS

8:00am – 4:30pm

EST

HOURS

8:00am – 4:30pm

EST